The high-performance biological compact reactor, called the CJR (Clausthal Jet Reactor), guarantees a remarkable oxygenation transfer rate of up to 3 kg O2/m3h (conventional aeration process up to 0,2 kg O2/m3h). In addition, during the biological process, it can achieve an oxygen utilization rate of up to 50 % and a bacterial activity content of 70 %. Compared to conventional treatments with an oxygen utilization rate of up to 15 % and a bacterial activity content of 35 %.

The CJR reactor uses a circulation pump that transports the mixed-liquor through a pipeline straight to the main element, a two-phase jet nozzle. One phase consists of mixed-liquor, and the other is air injected into the reactor as microbubbles. Due to the high velocities, the floccules become smaller making oxygen from microbubbles more available to bacteria.

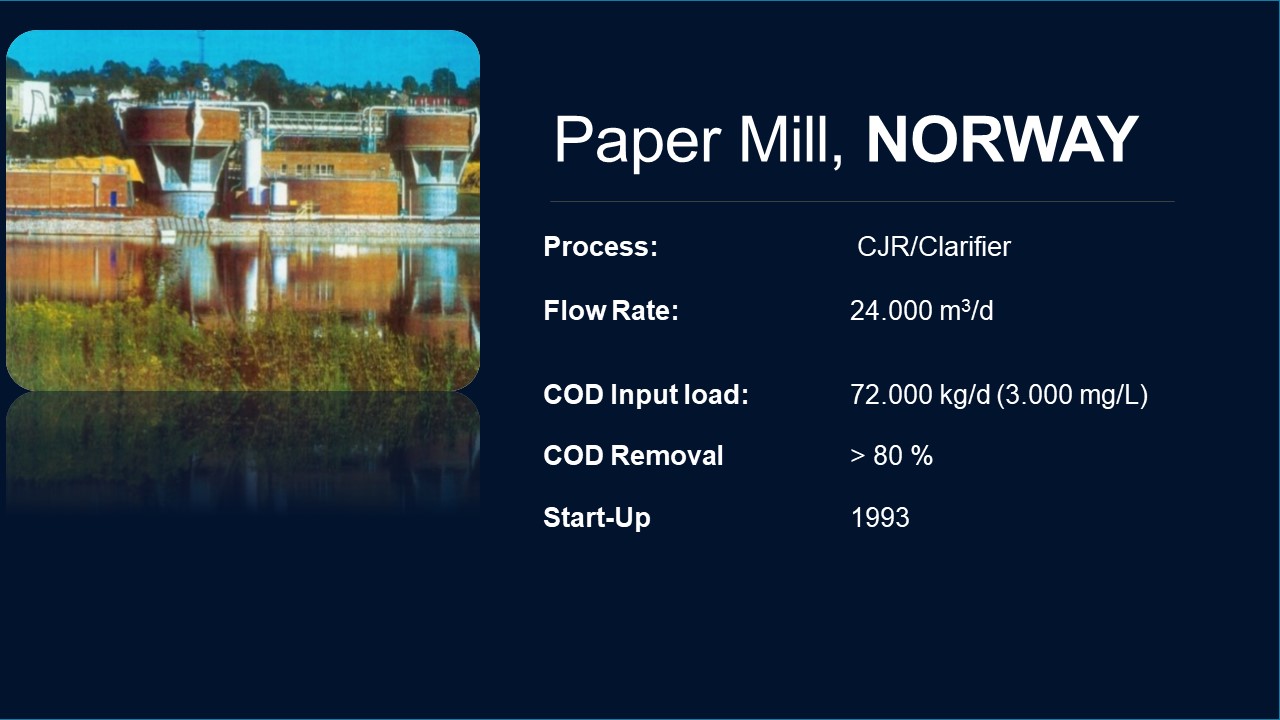

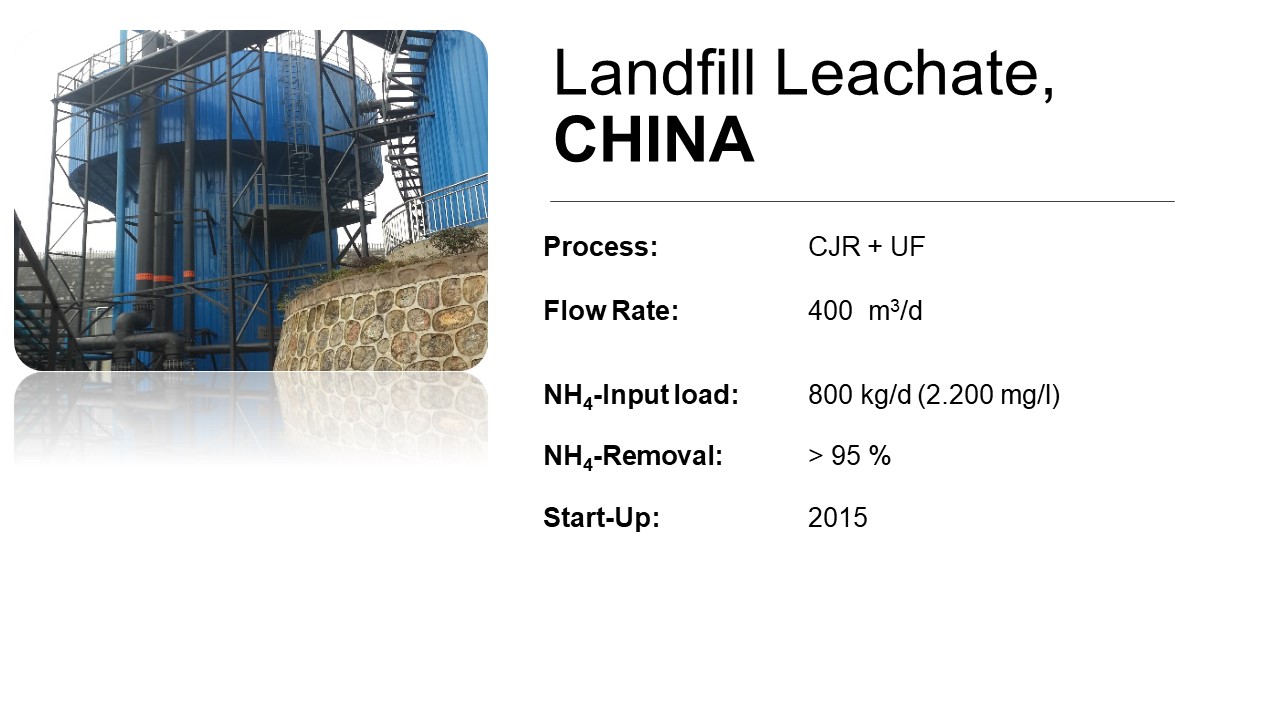

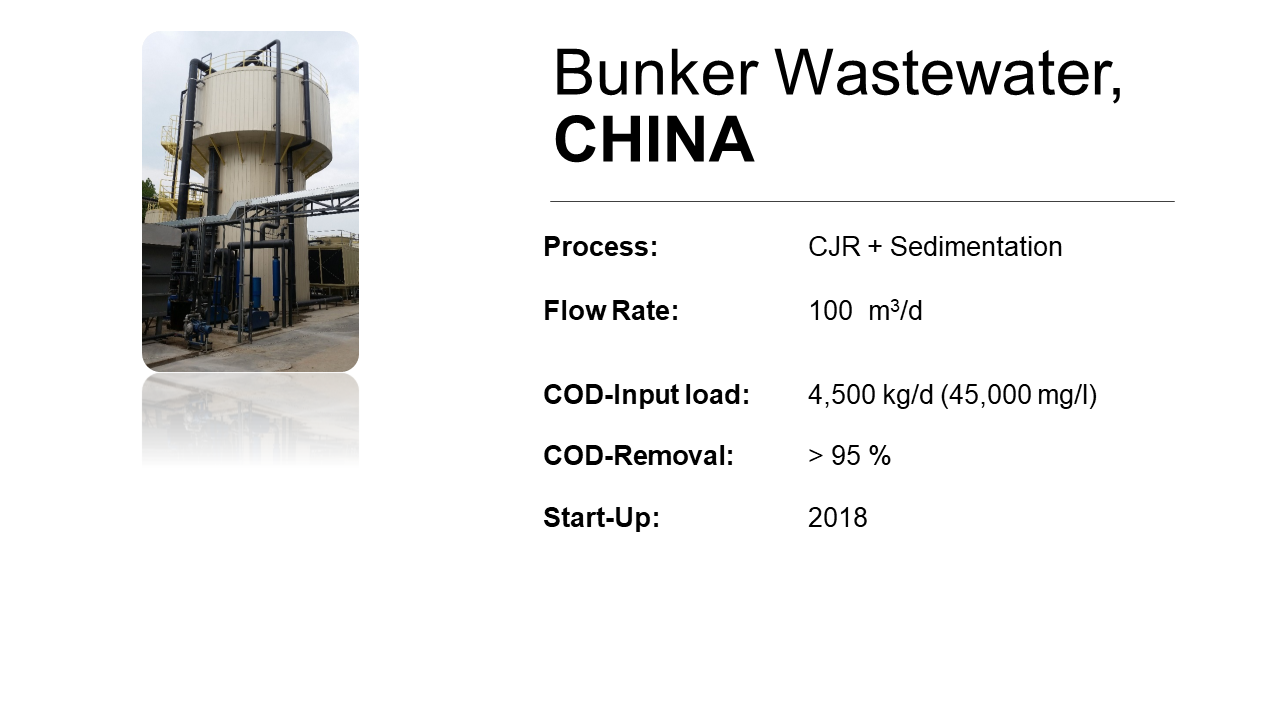

Worldwide over 40 full-scale plants with reactor volumes of more than 1,000 m³ are treating different wastewaters (chemical, food, pulp and paper, slaughterhouse effluents, etc.).